Hyundai's New €5.5 Billion Georgia Plant: A Robotics and AI Manufacturing Powerhouse

Hyundai Pioneers AI-Driven Automotive Manufacturing in Georgia

Hyundai Motor Group is making a significant investment in the future of car manufacturing with the grand opening of its new €5.5 billion (approximately $5.8 billion) plant in Bryan County, Georgia. This isn’t just another factory; it’s a showcase of cutting-edge technology, built from the ground up with artificial intelligence (AI) and robotics at its core. The facility represents the largest single investment in Hyundai’s history and signals a major commitment to the North American market.

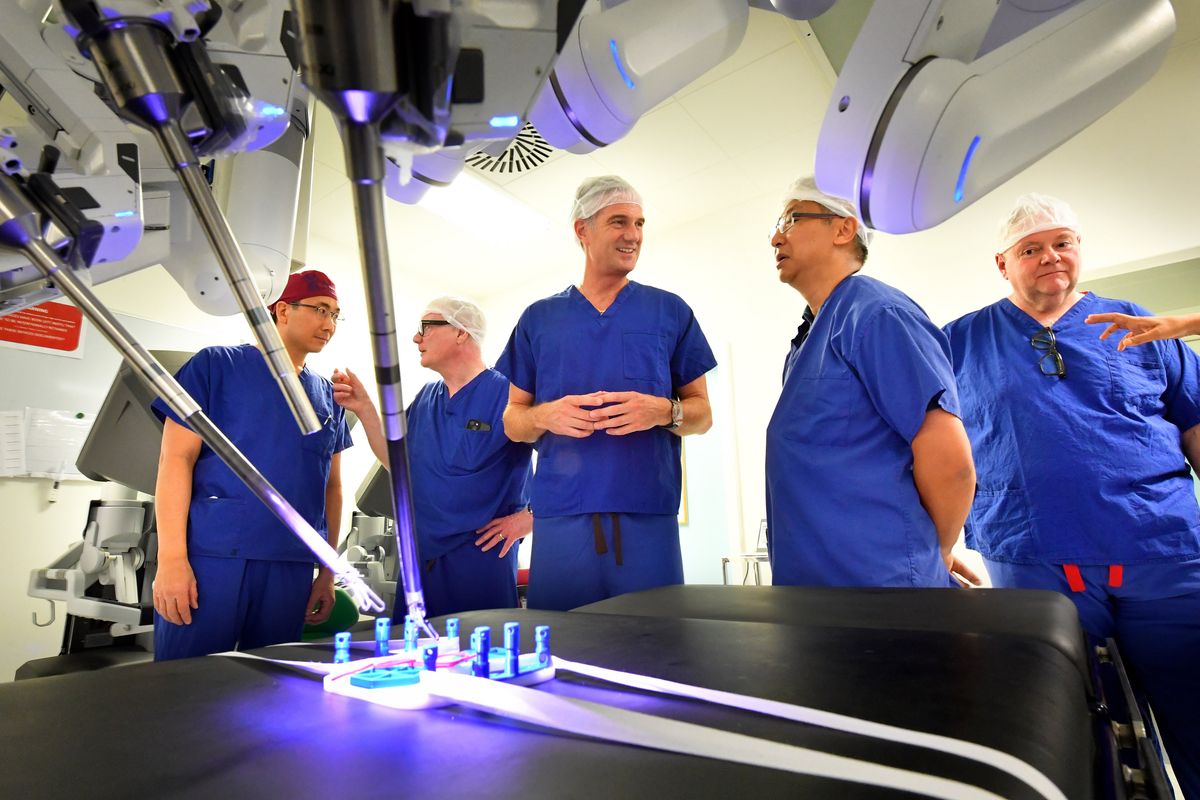

Robotics and Automation: The Cornerstones of Efficiency

The Georgia plant is designed to be significantly more automated than Hyundai’s existing facilities. Advanced robotics are integrated throughout the entire production process, from welding and painting to assembly and quality control. These robots aren't just performing repetitive tasks; they're working alongside human employees, collaborating to enhance efficiency and precision. This collaborative approach allows workers to focus on more complex and value-added tasks, while the robots handle the demanding and often physically strenuous aspects of the job.

Digital Twins: Simulating Success

Beyond robotics, Hyundai is leveraging the power of digital twins. A digital twin is a virtual replica of the physical factory, allowing engineers to simulate and optimize production processes *before* they're implemented in the real world. This dramatically reduces the risk of costly errors and allows for continuous improvement. By testing different scenarios and configurations virtually, Hyundai can fine-tune the plant’s operations for maximum efficiency and responsiveness to changing market demands. This predictive capability is a key differentiator for Hyundai in the competitive automotive landscape.

Nvidia Partnership: Powering the AI Revolution

A crucial component of this AI-powered factory is the partnership with Nvidia. Hyundai is utilizing Nvidia’s high-performance chips to power the AI algorithms that control the robots, analyze data from the digital twin, and optimize the entire manufacturing process. Nvidia’s DRIVE Hyperion platform, for example, is crucial for advanced driver-assistance systems (ADAS) and autonomous driving capabilities, and its underlying technology is being adapted for use within the factory itself. The chips enable real-time data processing and decision-making, ensuring that the factory operates at peak performance.

Impact on the Local Economy and the Future of Manufacturing

The new Georgia plant is expected to create over 8,100 jobs and generate billions of dollars in economic impact for the region. More importantly, it serves as a blueprint for the future of automotive manufacturing. Hyundai’s commitment to AI and robotics demonstrates a willingness to embrace innovation and transform the industry. The plant’s success will likely inspire other automakers to invest in similar technologies, accelerating the adoption of AI and robotics across the sector. This shift will not only improve efficiency and quality but also create new opportunities for skilled workers who can operate and maintain these advanced systems.

What to Expect from the Georgia Plant

The Bryan County plant is slated to begin production in the first half of 2025, initially focusing on electric vehicles (EVs) and EV components. The flexible design of the facility allows it to adapt to future production needs, ensuring that Hyundai remains at the forefront of the automotive industry for years to come. Hyundai’s bold move into AI-powered manufacturing is a clear signal of its ambition to lead the electric vehicle revolution and redefine the automotive manufacturing landscape.